With accelerating electrification, it is important to use solutions dedicated to industry. That’s why nVent RAYCHEM provided a complete and efficient electric heat tracing system for the High-Quality Coal and Dimethyl Carbonate (DMC) Utilization Project, which is currently the world’s largest coal chemical project. The project has been successfully commissioned at Shaanxi Coal Group in China.

nVent RAYCHEM provides a complete and efficient electrical heat tracing system to fulfill various needs of the glycol purification process, the Dimethyl Oxalate (DMO) device, and utilities. It also provides process temperature maintenance, industrial pipe freeze protection and other heat tracing application solutions, and successfully tackles the security challenges of the manufacturing processes.

Challenges of High-Altitude Regions

To overcome the challenges of high-altitude regions, nVent RAYCHEM achieved precise temperature control operation in a comprehensive and systematic way.

Yulin Chemical Co. Ltd is located in a high-altitude region where the lowest ambient temperature in Winter can reach -32.7 °C. The glycol project involves numerous devices. Therefore, the entire plant area needs to be provided with freeze protection heat tracing, and some process pipelines must be maintained at 25-40 °C.

nVent RAYCHEM Solutions

nVent uses a single-circuit controller for the precise surface temperature control of process pipelines, and centralized ambient temperature control for pipe freeze protection. This not only meets the precise temperature control requirements of the process pipelines but also realizes an effective total cost of ownership (TCO) and energy efficiency.

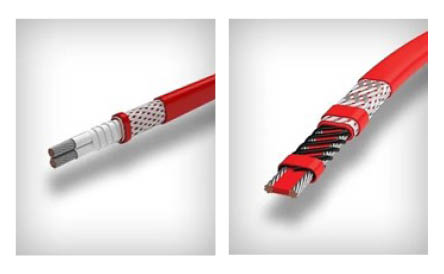

nVent RAYCHEM VPL and nVent RAYCHEM XTV high-temperature cables are used for temperature control and maintenance for high and medium-temperature pipelines in the DMO device. They have a total length of 9,000 meters, and the TCONTROL-04 precise temperature control system is configured to provide process data to achieve accurate temperature control, reduce downtime and increase productivity. The maintenance of a proper temperature in the pipelines ensures the safe and reliable operation of the devices and guarantees the quality of the final products.

Medium and low-temperature freeze protection of pipelines and other devices for the handling of glycol is accomplished by nVent RAYCHEM RTV and nVent RAYCHEM CTV cables and a cumulative length of 50,000 meters has been installed, this meets the requirements of the project for operating during the low-temperature season throughout the year. It also avoids pipeline freezing to ensure smooth and safe production and transportation processes under low temperatures and harsh conditions.

The complete and reliable EHT system ensures stable operation and accelerates the project’s output.

Yulin Chemical Glycol Project has been officially put into operation. The entire series of ethylene glycol device systems operate smoothly, achieving full process connectivity and output. Operation of the nVent RAYCHEM heat tracing system was safe and reliable during the commissioning of the critical devices throughout the plant. After a number of trial-run operations, the quality of the final product was guaranteed.

nVent RAYCHEM has excellent technology and rich experience in the R&D, design, production and engineering services of EHT systems, making us an ideal and reliable partner for customers in the global coal chemical industry. We will continue to vigorously boost coal chemical industry development with nVent RAYCHEM energy-saving technology and contribute to the green energy revolution.